Original Prusa i3 MK3

Reviews

Please sign in or register to add your own review.

Assembly

i3 mk3 kit (Own work. License: CC-BY-SA.)

Kit arrives in box with several smaller boxes inside for the sub assemblies. Everything is well organized and labeled. The kit comes with tools for assembly, 1 kg of PLA and gummy bears. Assembly of the kit took around 12 hours and can be tedious. Be prepared to spend much more time than that if you aren’t experienced with this kind of work. Assembly instructions were generally good but, use the online version so you can see comments where people had trouble or the instructions were confusing. The tuning once the printer was assembled takes patience and is a bit unsettling. It has you do a pre-programmed print and adjust the z axis down while printing to calibrate extruder to print bed relation.

The belt tightening on the x axis is bad. Pull as hard as you can or you’ll find the belt is too loose even with the tension adjust and have to take the back off the x carriage again. Be careful, the tension adjustment will crack the mount with no notice! Also, high belt numbers mean loose belt, low numbers mean tight belt so if you’re above 280 go back and tighten your belts.

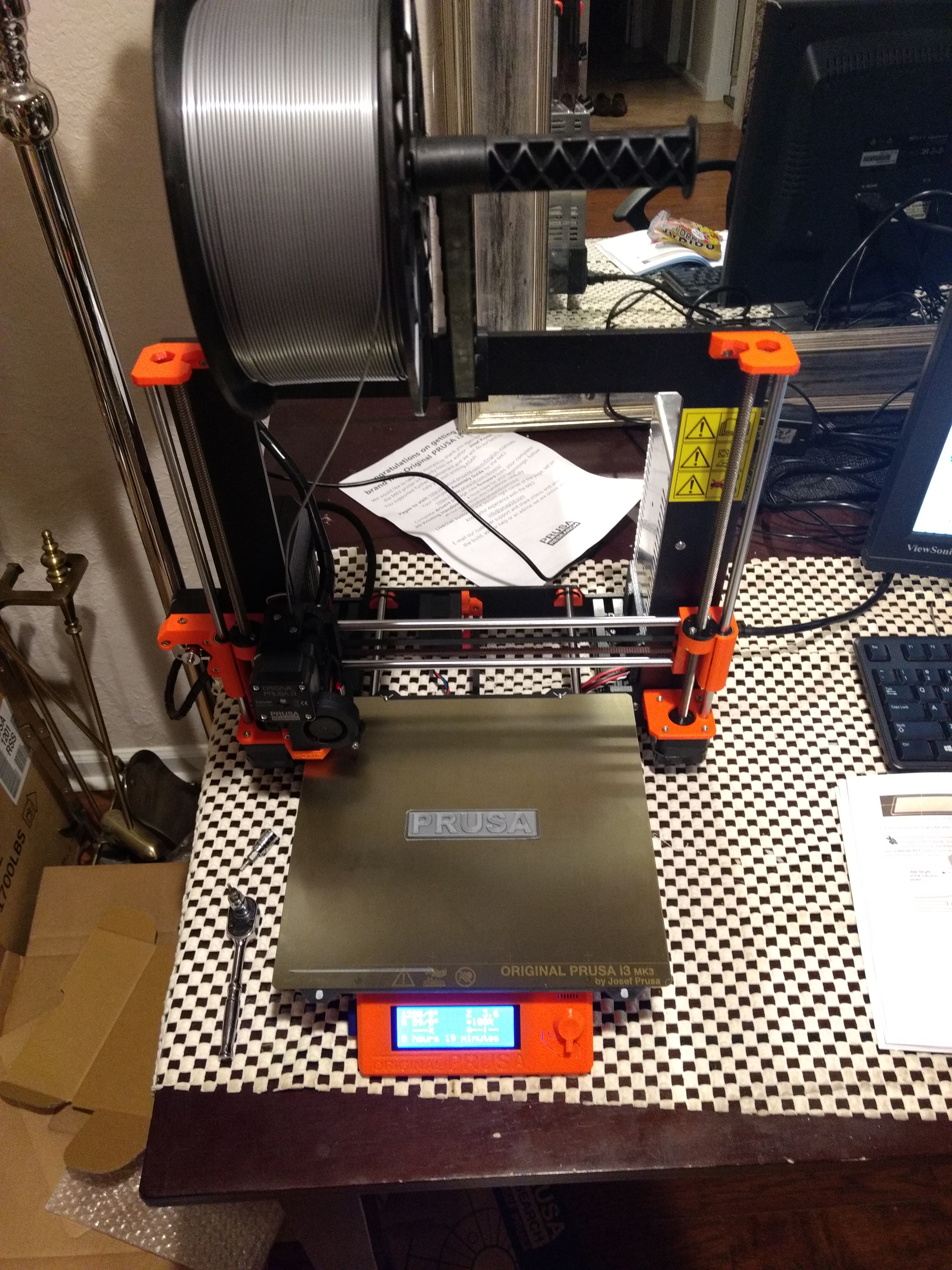

Assembled i3 mk3 (Own work. License: CC-BY-SA.)

Software

I use Slic3r Prusa edition to create gcode for the machine. The integration is very well done with the defaults for the printer being loaded in automatically. Default settings have been turning out quality prints. PrintRun(pronterface) had no issue connecting to the machine and running prints.

Printing

PLA

Printing parts in pla on the default 0.2mm fast profile with 20% to 80% infill. First layer is consistently good without a brim or raft. Some features have had small issues on the first layer where there’s sharp corners or tight radii, but they rarely cause issues with the overall print. Prints pop off the PEI sheet easily and if you have trouble the entire sheet can be removed and bent.

PETG

The first spool of prints went well with default 0.2mm fast profile and 20 to 50% infill. Consistently good first layer without adjusting live z from PLA setting. Bed adhesion is good if bed is clean, dust or oil from your finger will mess up the first layer. Print will pop off with a bend of the sheet when cold. Stringing is there but easily pulled off. The next 2 spools have not printed well, but I narrowed that down to bad material.

Material since then has been printing fairly well assuming live z is set well and nozzle is clean.

Updates

The printed printer parts, software and firmware are all getting continuous updates from Prusa Research. This made me confident the machine will be well supported throughout its useful life. After a few months of ownership, it’s clear that the updates can often be beta quality with new features being disabled in the next up date, then reenabled a few updates later.

Smart Features

The filament sensor has been OK. It came disabled by default which was suprising and caused me to lose a print. It worked fine to autoload filament the few times I used it. Currently, it isn’t being recoginized by firmware. The crash detect feature has been a dissapointment as well. I have never had it recover from a crash without a layer shift of at least 0.6mm. Power panic has been tested once and failed to recover from a ~3 second power loss when the power strip was accidentally switched off. PINDA probe came with temperature compensation switched off. This means mesh bed leveling will not be correct if PINDA is hot(typically 35 C or higher). Go to Settings>Temp Cal to turn on. Then run temp calibration to set the temp compensation. You may want to manually set it using manual temp calibration since the automatic calibration isn’t very good.

Long Term Update

After a couple months with the printer, issues are starting to come up.

Bed

The steel sheet will develop bubbles underneath the PEI from prints. The bubbles have been deemed normal by Prusa Research and tend to come and go. They will not go away if you print the same part in the same spot meaning you can’t print the same parts without moving them around the bed. PEI is likely to get damaged over time if printing PETG. A well adhered print ripped off a piece of PEI after 3ish months.

Bed is now up to .25mm out of level with no mechanical adjustment available.

Power Supply

Power supply died after approximately 3 months with approximately 1 month inside enclosure. This was indicated by the input fuse blowing loudly.

PINDA

The bed leveling/ first layer issues I had were partially created due to faulty PINDA probe(outside of its lack of temperature compensation). After replacing the probe with a BLTOUCH, its clear the probe was defective and part the issues I was having.

Z Axis Sync

After getting my printer working again with the BLTOUCH, the Z axis is losing sync. I tracked the issue to a failed lead screw nut.

Verdict

Decent machine that can produce good prints until the hardware breaks down. This printer packs a lot of features in for the price but the company is not doing a good job of integrating new features and the hardware is unlikely to last. It’s clear Prusa Research relies heavily on feedback from the community to test products so you should avoid buying new models until community has had time to point out flaws and the company has time to reintegrate those changes.

About

-

-

Show uploaded media

Uploaded media: